Memorable Times

Journalism Students Visit the New York Times Printing Plant

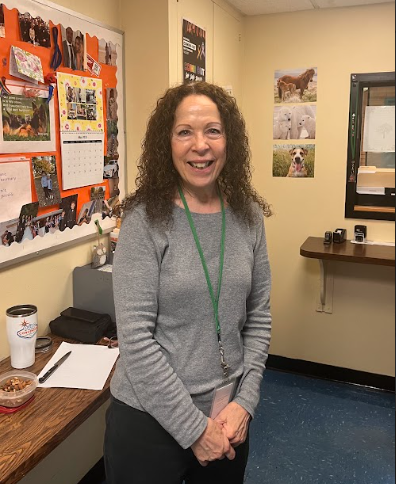

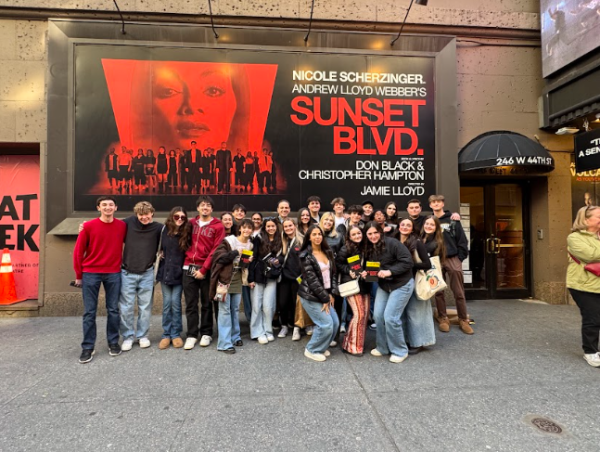

This year, due to the political climate and recent presidential election, newspapers nationwide have reporting having their busiest year since 9/11. This remains true for American daily newspaper, the New York Times. Journalism students and members of Horizon visited the New York Times printing plant, located in College Point, Queens, on Oct. 20 with English Teacher and Horizon Advisor Jessica Sanders. While visiting, they learned about the production process behind the popular paper.

The bold, colorful, and dynamically shaped building contrasts from the lot’s previous tenant, an NYPD impound lot. Built in 1997, the modern and environmentally friendly building is constantly updating to fit with new technology. The students were given a tour of the work space where the newspaper is finalized and printed in mass production. They saw portions of the 300,000-square-foot plant and the 14 miles of conveyor belts it holds. In the plate room, they watched as the articles were lasered onto thin aluminum plates that would soon be used in the printing process. Next up was a visit to the reel room. The reel room, a large open space where the newspapers go immediately after being printed, is covered with fans spraying mist to regulate the rooms’ temperatures and humidity, ensuring the news paper will stay in optimal condition. They then saw utility “robots” transport massive rolls of blank paper, weighing in at one ton each. Overall, the students learned how the New York Times has benefited from technology and the role the plant plays in almost every aspect of printing.

In addition to seeing utility robots and the complex printing machines, students spoke to New York Times Chief Operations Manager Mike Connors, and who gave an important lessons not only about how to prepare for future careers in journalism, but about life in general. They also learned about the 26 printing sites for the paper and how they deliver the paper to other parts of the country. New York Times’ paper is a national product, and special features printed in New York are shipped to areas such as Chicago solely by truck. Connors, as an employee and tour guide who has worked for New York Times for 41 years, spoke about the trucking process, the possible errors they may encounter, and how the “Times” works to prevent them to ensure all readers are satisfied with the product.

Students also learned about the business side to the paper, including advertising and the differences between print and online revenue. According to Connors, “Print is where the money is. Sixty-fiver percent of the company’s revenue comes from print. Because of this, we have to be careful not to compete against ourselves and allow the online version to overpower our print version… Realistically, I can never see the ‘Times’ going completely online.” Fortunately for its readers, the New York Times has already signed contracts ensuring it will continue to print for the next 12 years. Connors discussed how Horizon’s staff can work to ensure both the online and print edition of the paper remain relevant, and he suggested some advertising tactics to help increase funds.

Sophomore Andie Glanzer, as student on the trip, said, “The trip was very beneficial. We learned a lot, and some of it can even help us with our own paper and future careers. I was surprised with the printing process, but I’m glad I now better understand it and have much more appreciation for newspapers…Overall, I enjoyed the field trip.” Freshman Emily Bergin agreed, stating, “I learned a lot about journalism and how the industry works from the man who gave us the tour. It taught me how fast the industry really moves… I would recommend the trip to future students. It was very interesting.”

I am a member of the Class of 2020. In my free time, I write articles for Horizon. I am the editor-in-chief for the print edition for 2019-2020.